THE APPLICATION OF PERMA-ZYME

THE PROCEDURE

It is important to decide how much work will be undertaken on any given day. Once decided the following is the method in which PermaZyme will be applied and the road constructed.

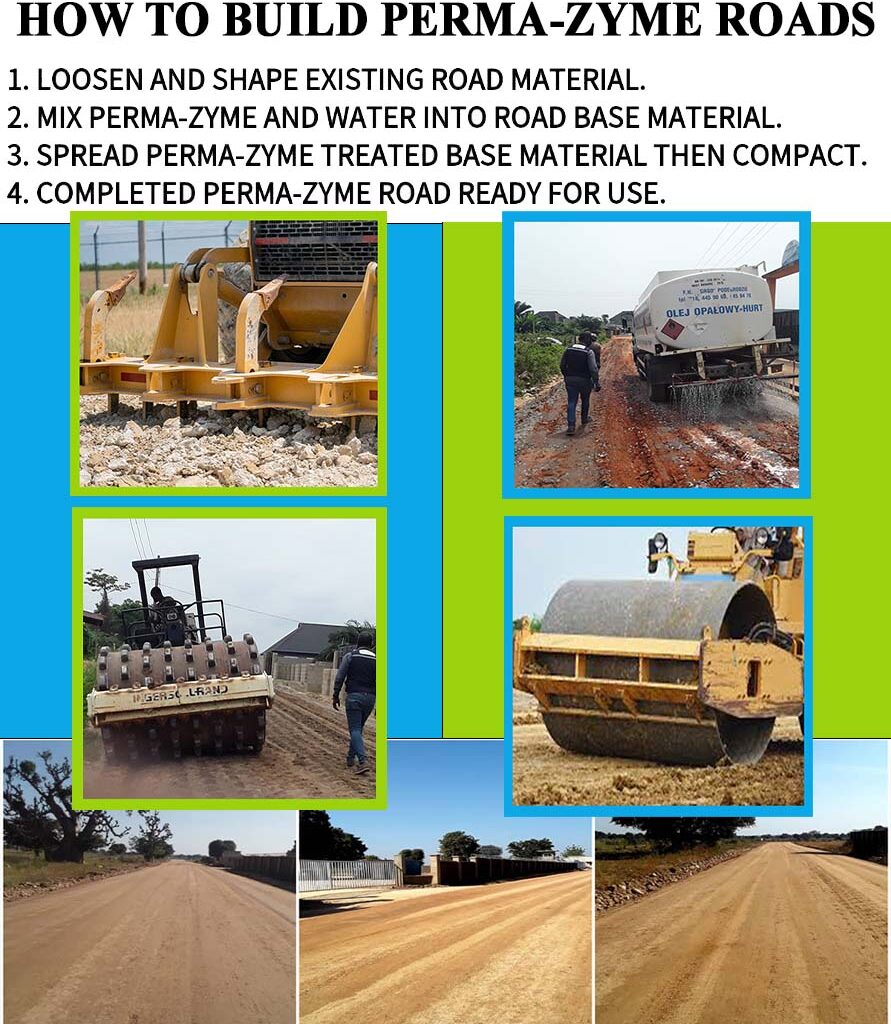

- Scarify the existing pavement

- Blade into windrows.

- Wet the base with the PermaZyme and water mix.

- Continue to blade mixed materials while adding PermaZyme and sufficient water to

achieve optimum moisture. - Compact materials to required or specified densities

Trim and slurry the surface using a 10,000:1 solution of water: PermaZyme for the final finish (if required).

As the above procedures are consistent with normal water binding procedures the work crew should have little difficulty with the steps involved. What is critical for the supervisor to ensure is that the PermaZyme is added evenly into the soils. One of the first jobs undertaken is to ascertain how much water will be required for the day. Then the crew is to be instructed as to how much and from which water tanks the PermaZyme goes into, using the following parameter as a guideline.

PermaZyme is to be applied using as much of the water needed on the day as possible but also ensuring that the soils cannot reach optimum moisture before all of the required PermaZyme is used. This may sound complicated. It is hoped that the example given below will simplify this guideline.

Use water only to bring soils to optimum moisture content thereafter.

It is always a good idea to bring the crew together beforehand if it is their first application to explain the process to them. It is also critical that the method of operation of the team is not changed or altered unless there are serious flaws in their road-building techniques. This is a highly unlikely scenario, but it has been known to happen. If their process is changed there will be obvious effects on overall efficiency. Only change those parts of the process that must be changed.

As soon as the road has been boxed out it is then time to commence the use of PermaZyme and water (depending upon the in-situ moisture, the water truck may often make a small number of passes to help loosen the materials or the boxing out process). The main task for this part of the day is to ensure that the water trucks are making even passes so that the PermaZyme penetrates the soil as evenly as possible. Moisture checks are very important as atmospheric conditions can influence moisture retention in the soil quite significantly. Once the materials have been blade mixed satisfactorily and wetted uniformly, the compaction process can begin.

A Metric Guide

1 Km X 6.5 m X 150 mm = 975 m3 compacted material Assume Density = 1.98 t/m3 (from MDD test) = 1,930.5 tons of material

If optimum moisture content = 10 % = 193 tons of water.

Let us assume in-situ moisture of 7% = 57.9 tons needed to reach O.M.C. = 58,000 liters approx.

If water carts hold 10,000 liters = 6 trucks of water/km.

If the weather is expected to remain fine then put the required PermaZyme into the first 4 trucks.

You may find that each crew has its own style of road building process. Some crews will wait and put more energy into the mixing process than others. Consequently, they may not bring on the rollers until much later in the day. The more uniform the wetting and mixing, the less chance there is of lamination. Once the materials have been laid on the road and the compaction has started, it is time to grid out the road and take a series of compaction values as dictated by the laboratory testing.

Depending on the circumstances two to three sets of these will be taken over the space of a day. When the soil is compacted to specified values and at optimum moisture content we can now be assured that the benefits of PermaZyme will be Optimized. Prior to the finish of every day it is important that each section of the project is checked to ensure that an adequate camber has been built into the road and the water run-off is Optimized. It is always

good to fix any potential drainage problems, which might arise as a result of blockages in the table drains. It is now common practice for most road crews to slurry finish unsealed roads to bring the fines to the surface thus creating a natural seal. It is useful to include PermaZyme in the slurry tank as mentioned above (only if required). It will help consolidate the fines on the surface but not over wet at any stage.