about us

PERMA-ZYME, a concentrated enzyme formulation, uses the properties of earth material to produce superior road base stabilization.

Within 72 hours, the level of firmness achieved with soil (sand, clay, or gravel) appropriately treated with PERMA-ZYME is significant (CBR values of greater than 100 % as well as the compressive strength of 1.5 N/mm² can be reached).

The road profile is very important in the construction of a dirt road and should be between 5% and 6% of a central crown. Compaction is done from the center out on both sides so that the integrity of the crown is not changed.

Drainage:

Table drains and culvert design are in the hands of the design engineer. Any fault in this area is not the fault of the product or the workers on the day of application.

Delamination:

Is caused by layers of soil being compacted at different moisture contents, and the use of heavy steel drum rollers usually in vibration mode. This will happen no matter what is used, from plain water to stabilization products, including lime and cement. Moisture content must be controlled at all times from wetting out the base to layers and final trim. Good work practices are essential.

Compaction:

This is a large subject and has many different viewpoints held by academics and engineers worldwide. Almost all of these views are held and vented on non-plastic soils, and the teaching in general is to exclude clay from any construction where possible. For clay

areas where highway construction is in progress, all forms of compaction will be used, and mostly in this order: sheep’s foot, steel drum, and rubber tire.

PermaZyme and Dirt Road Construction:

Dirt road construction is low-cost and is the finished product. It does not usually come under the same strict design control as highways. Good work practices must still adhere to at all times. Ideally, all three-roller types should be used during construction, but excellent roads have been constructed using nothing but the steel drum roller, and the water truck used as the rubber tire roller. The point here is that a steel drum roller will bridge soft spots, but the wobbly tire roller will not. Potholes can be the result of poor compaction. Rubber tire rollers

give a better finish to fine soils, and dehydrate the moisture far more rapidly. (Heavy traffic will accelerate the curing, and help seal the surface.)

Rain:

Should be avoided at all times. If rain is expected on the day of construction, use the local knowledge available to gauge the extent of rain that is normal, and use as little water as possible to apply PermaZyme to the soil. Use the rain instead of the water truck and con-

continue to work the soil ready for compaction. It is most important that the road is fully compacted prior to leaving the site. If heavy rain suddenly appears from nowhere, and you are

in the middle of construction, simply grade all treated soil into one windrow and layout later, or when the rain stops, up to seven days after the application of PermaZyme. On returning, make sure the base has moisture content equal to the treated soil to be laid so that delamination does not occur. PermaZyme at 10,000 to 1 in the water truck during this procedure will help ensure sufficient.

PermaZyme works will always get great results. Perma-Zyme has three main elements. One concern is where moisture is in abundance (rain), which may diminish the very sophisticated surfactants in the formulation. These surfactants are used to get into the clay-based soils, and take with it the other two very important elements. They also render the water ten times wetter than water alone, and increase the drying time to allow for a slow cure to eliminate cracking and shrinking. So you can see that if you then add more moisture, you are headed for major problems.

Conclusion: good profile, compaction and finish are paramount, and then all rain will end up in the table drains where it should be. If rain is forecast do not start the construction. The first priority is proper soil analysis. PermaZyme itself is a 100% perfect solution, but stipulated procedures must be followed exactly to ensure ideal results.

FAQ

How much Perma-Zyme is needed?

While the amount of water needed will vary from application to application depending on the soil and optimum moisture, the amount of Perma-Zyme will never change.

For example, if the road constructed is a two lane (7.3metres wide) 1kilometre long (7,300 sq.m) road and will be 150mm deep the application will require approximately 2,440 cubic yards of soil and 38 litres of Perma-Zyme

What kind of soils will Perma-Zyme work with?

Perma-Zyme’s best feature is that it is extremely versatile and works with a wide range of soils. When using Perma-Zyme the soil should be comprised of 15-20% cohesive fines. It is important to have a wide variety of material sizes in the soil to increase shear strength and internal friction which increases the load bearing capacity of the soil.

Perma-Zyme is used mostly in applications in which the soil is comprised of 15-20% cohesive fines but has been used in applications outside of the targeted range and performed well. Upon beginning any application of Perma-Zyme it is recommended that a test is performed to ensure Perma-Zyme will yield the proper results.

To have your soil assessed for free, contact us.

Will Perma-Zyme work with asphalt and/or chip seal construction?

Yes, Perma-Zyme is the perfect foundation for an asphalt or chip seal construction road. When using Perma-Zyme with a chip seal application, apply Perma-Zyme as detailed in the normal instructions and allow 72 hours to fully cure. Prior to the chip seal application spray a small amount of Perma-Zyme diluted with water (approximately 1000:1) to allow the chip seal application to bond to the base layer.

What is the normal process for applying Perma-Zyme?

A typical application for Perma-Zyme consists of 5 steps:

Grind or shred current road and soil until thoroughly mixed and a sieve test produces 15-20% cohesive fines.

Spray Perma-Zyme and water on soil until optimum moisture is achieved. Mix soil consistently by grading the soil from side to side at different depths.

Grade the soil to the desired road dimensions and path

Using a compactor, compact the soil in 3-6” lifts depending on soil and application until desired density is achieved.

Allow 72 hours for Perma-Zyme to fully cure.

For more information request our training videos here.

What kind of equipment is necessary for Perma-Zyme application?

Having the proper tools for the job is extremely important to ensure your Perma-Zyme application will succeed. Substrata recommends the following equipment:

Water tuck

Motor Grader (Caterpillar 140H or equivalent)

Padfoot (Sheepsfoot) Compactor (NOTE: Not required but very beneficial to have)

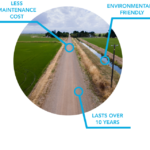

How long does Perma-Zyme last?

The life span of a Perma-Zyme road depends on many factors including traffic, weather, water drainage, and paved vs. unpaved. Roads with a dirt surface typically see a lifespan of 8-12 years while paved roads see a lifespan in excess of 20 years.

Are Perma-Zyme roads able to be repaired?

Yes, for dirt road construction Perma-Zyme diluted in water can be sprayed on the soil to deactivate the soil’s cementation and allow the soil to be moved and manipulated. After achieving the desired shape and form of soil allow 72 hours for the soil to fully cure.

When chip seal has been used, traditional chip seal repair procedures can be used.

What makes Perma-Zyme different from traditional road construction applications?

Perma-Zyme’s most unique aspect is that it allows the native soil to be used and does not require transportation of any soil or rock for the base layer of the road construction. Because Perma-Zyme can use the native soil the construction costs will be greatly decreased and will save time on the construction phase. Because of Perma-Zyme’s unique cementation effect it produces a strong and robust base layer that will lead to a long-lasting road.

Experience

why choose us

- Traffic Loads (wheel weight & frequency of use)

- Available road building materials.

- Topography & sub-base soil conditions (soft or firm).

- Moisture (rain, snow & ground water).

- Long term use and maintenance requirements.

+2348123446577

CEO Permazyme Nigeria